Vacuum Pump Used To Create A Partial Vacuum Within A Closed System By Removing Gas Or Air Molecules

|

| Vacuum Pump |

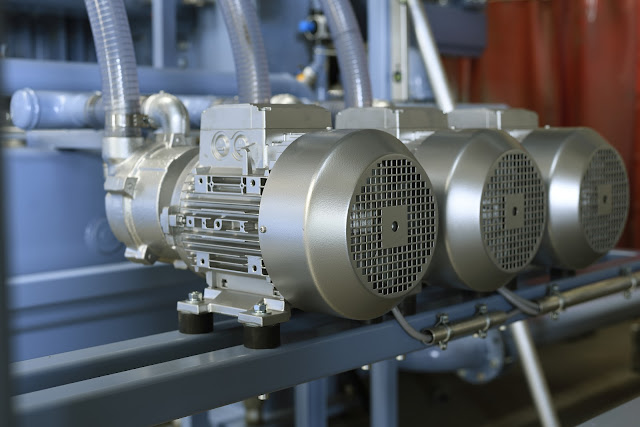

A

Vacuum Pump is a mechanical device

used to create a partial vacuum within a closed system by removing gas or air

molecules from the enclosed space. It finds applications in scientific

research, and everyday life. The fundamental principle behind its operation is

to decrease the pressure within a chamber or container below the atmospheric

pressure, thus allowing the removal of gases or creating a space devoid of air.

The

history of pumps dates back to the mid-17th century when the first rudimentary

pumps were developed to assist in scientific experiments. However, significant

advancements were made during the 19th and 20th centuries, leading to the

development of more efficient and versatile pumps.

According To Coherent Market Insights,

The Vacuum

Pump Market Was Estimated At USD 6.07 Million In 2022, And From That Year

To 2030, It Is Predicted To Increase At A CAGR Of 7.29%.

One

of the earliest and simplest Vacuum Pump is the manual suction pump, known as the

"suction pump." These pumps rely on human effort to create a vacuum

by pulling a handle or using a piston to lower the pressure inside a chamber.

While effective for certain applications, they have limited applications and

are mostly replaced by more advanced technologies today.

Modern

vacuum pumps come in various types, each suited for specific applications. One

of the most common types is the "rotary vane pump," which uses

rotating vanes to compress gas and move it out of the pump. These pumps are

widely used in applications such as refrigeration, air conditioning, and

automotive systems.

Another

important type is the "diaphragm pump." This pump utilizes a flexible

diaphragm to create a vacuum by alternately expanding and contracting the space

inside the pump chamber. Diaphragm pumps are oil-free and are commonly employed

in laboratories and medical devices.

For

applications requiring a high level of vacuum, "diffusion pumps" are

used. These pumps work on the principle of diffusion, where gas molecules are

directed toward the outlet by a high-speed jet of vaporized oil or metal.

Diffusion pumps are essential in vacuum deposition processes and manufacturing

semiconductors.

Other

types of Vacuum Pump include

"scroll pumps," which use two interleaved spiral scrolls to compress

gas, and "turbomolecular pumps," which achieve high vacuum levels by

utilizing rapidly spinning blades to propel gas molecules out of the system.

Mechanical Pump

Seals are specialized

components used in pumps to prevent leakage of fluid along the rotating shaft.

Consisting of sealing faces and a spring mechanism, these pump seals provide a

secure barrier, maintaining fluid containment and minimizing energy losses

during pump operation.

Vacuum Pump has found widespread use in scientific research and

laboratories. They are crucial in creating controlled environments for

experiments, handling delicate samples, and enabling techniques like

freeze-drying. In the medical field, vacuum are used in various applications,

including suction devices during surgical procedures and vacuum-assisted wound

healing.

Comments

Post a Comment